Moisture Capacity of Air

Dual Tower Desiccant Air Dryers

Contrary to the best intended opinions of those who feel the only way to dry and condition compressed air is by applying desiccant dryers on a 24 hr., 12 month per year basis ---the application of a refrigerating air dryer during the summer months can be a viable and more economical option.

- Apply existing desiccant dryer during winter when pneumatic valve freezing can be a problem.

- Switch over to the refrigerating dryer during summer where a pressure dew point of 36 to 39° F is acceptable.

- Savings will be gained in reduced desiccant dryer maintenance and reduced energy consumption.

Maintenance items on (heated) regenerative dryers include heating element failures, switching valve repair or replacement, blower failures, pre and after filter elements and above all the tower desiccant bead replacement every 2-3 years if the required winter dew point of –40° F is to be attained.

Heatless dryers can be costly to operate due to their high consumption of dry compressed air for wet tower purging---may be up to 15-17% of dry air volume.

Desiccant Dryer Overview

Desiccant Dryer Overview

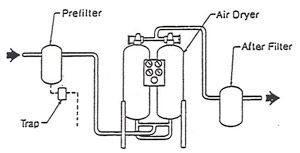

Prefilter - removes dirt, oil, and water

Dryer – Removes water vapor

After Filter – Removes fines to protect the system from contamination